Navigation

Kaili testing center is equipped with various complete testing equipment to ensure the quality of incoming, process and outgoing products. Its main testing capabilities include: chain length and tensile test, sprocket impact test, sprocket density test, material spectral analysis, metal and plastic hardness, cleanliness, roughness / profile / cylindricity measurement, coordinate measurement, metallographic analysis, tensioner /vvt comprehensive performance test, destructive test, drop test , comprehensive vibration test, salt spray test, high and low temperature alternating test, spring fatigue test, etc.

It is mainly used for raw material inspection, casting quality appraisal or metallographic structure analysis after material treatment, as well as research on some surface phenomena such as surface cracks and spraying. It is the metallographic analysis of steel, non-ferrous metal materials, castings and coatings.

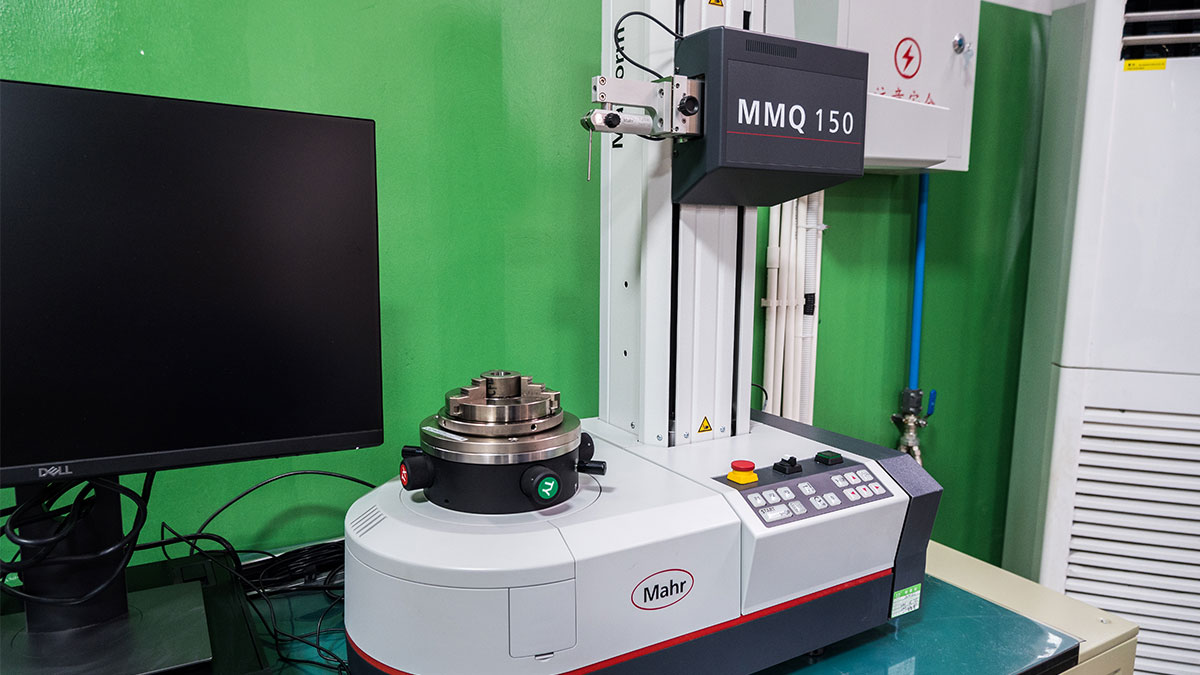

It mainly detects roundness, coaxiality, runout, perpendicularity, parallelism, surface waviness and other shape and position tolerances.

The profile measuring instrument is a precision equipment for measuring the shape of various mechanical parts' prime lines and cross-sections. The worktable of the instrument adopts high-precision horizontal air floating track and rolling vertical track, with high moving precision, good stability and high measurement efficiency.

It includes electric plastic Rockwell hardness tester, Rockwell hardness tester, shore hardness tester bracket, digital display microhardness tester, electronic Brinell hardness tester, etc. it is used to test the hardness of metal and plastic materials.

10nm spring torsion fatigue testing machine is used for torsion fatigue life test of torsion spring, scroll spring, spring, etc.

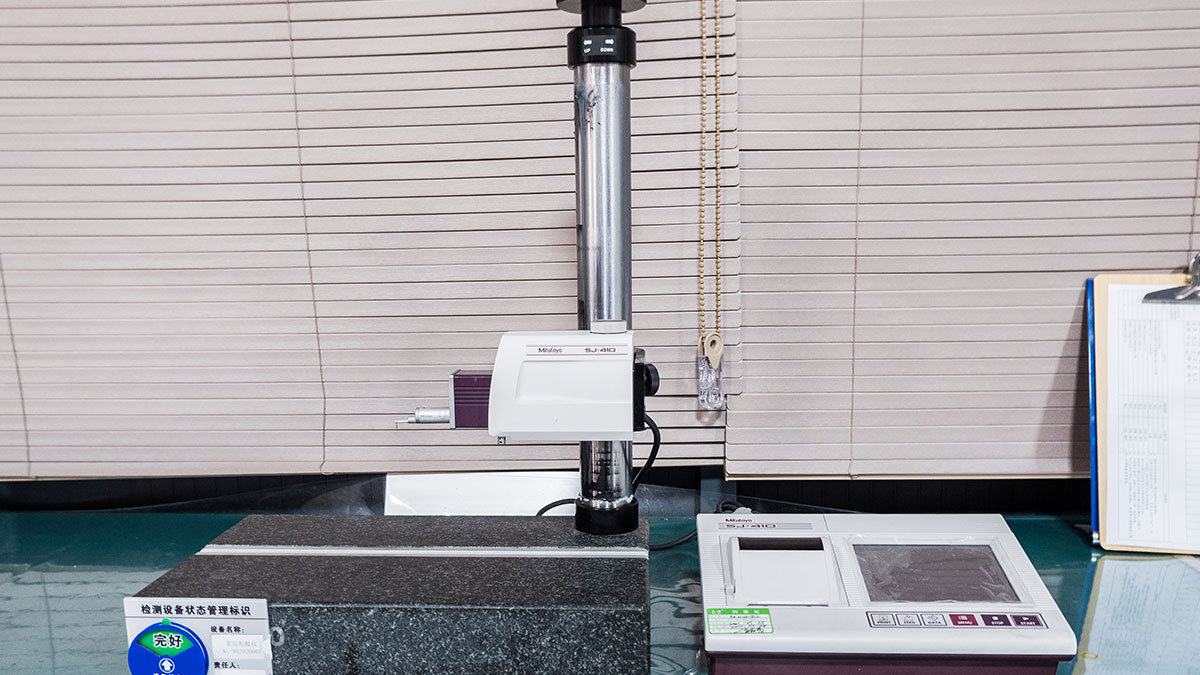

The measuring method of using the measuring needle of the instrument to contact with the surface to be measured, and making the measuring needle slide gently along its surface to measure the surface roughness is suitable for measuring the roughness of the plane, inclined plane, inner and outer cylinders, grooves and axle surfaces of parts, with less measuring time and convenience.

When the product passes through an arc or spark, the emission spectral line intensity of each element is directly proportional to the content of the element in the product. The content of each element is analyzed by detecting the energy of the emission spectral intensity. Applied to composition analysis of steel, iron, copper and aluminum alloy materials.

The salt spray test chamber is applicable to the salt spray corrosion test of parts, electronic hardware components, protective layers of metal materials and industrial products.

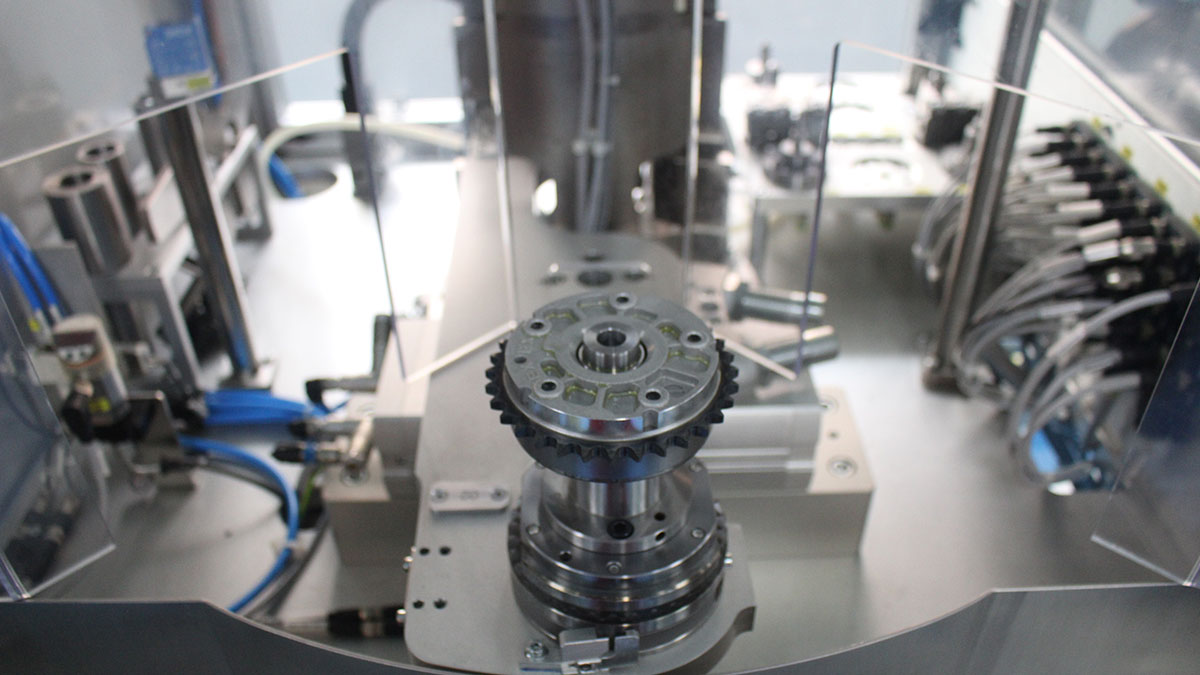

It mainly tests VVT starting pin pressure, friction torque, leakage, locking test, locking pin clearance, etc., so as to judge whether the comprehensive performance of VVT meets the design requirements.

Check and judge whether the locking pin performs the unlocking action under the specified oil pressure and whether the assembly will be stuck without oil lubrication. Currently, Kaili adopts 100% performance test on the VVT on the installation line to ensure that each VVT is in the best performance state.

Put the measured part into its allowed measurement space, accurately measure the values of the points on the surface of the measured part at three coordinate positions in space, process the coordinate values of these points by computer, fit them to form measurement elements, such as circle, ball, cylinder, cone, curved surface, etc., and obtain their shape, position tolerance and other geometric data through mathematical calculation.